When a consortium of steel manufacturers and automakers needed to know if Advanced High-Strength Steel really could be formed in ways predicted by computer models, it enlisted Autodie to get the answers.

We provided the brainpower and resources to build a specially made die with sensors that told us loads and strains as AHSS is drawn and formed so we could run trials that bracketed in what happens and where it happens during the stroke. We continue to add to the overall understanding of how to form that material by performing experiments in Grand Rapids regularly.

Our work with AHSS is only one example of how customers tap us for our intimate knowledge and experience in the best ways to draw and form mild steel, stainless steel, aluminum and exotic materials.

But that’s only the starting point. Our philosophy is we have one chance to get everything right in initial die design and engineering because changes past that point can be errors that cost time and money. And we approach every job with that same philosophy, whether it is a one-hole pierce die for a wheel or a complex bodyside.

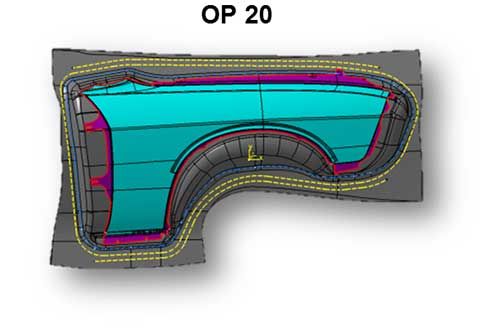

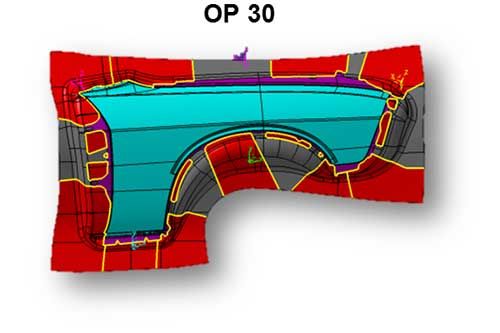

Our designers and engineers start with the die processing step where they use Catia and NX software programs to generate 2-D die processes or 3-D die processes to show how a part is manufactured during draw, trim and form. Our overall goal: give our customers the least number of operations that will produce dimensionally correct parts, based on their capabilities and equipment.

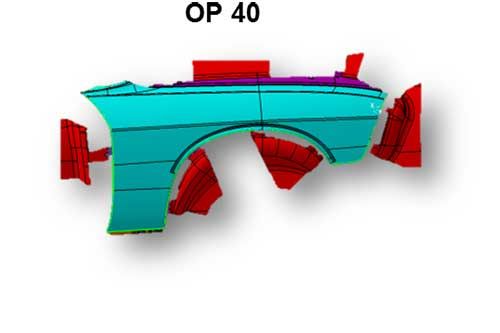

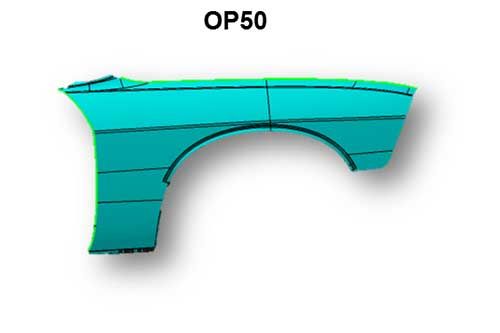

We then perform finite element analysis of the tools and simulation using Autoform to verify if the process is feasible for the part as it is designed. We engage our customers in conversations of possible design improvements to the part so they can have the most robust manufacturing process possible. Along with our extensive experience of working with many different parts from several industries, we also use the latest software tools for accurate modeling. Autodie was the first company in North America to use the Autoform segmenting tool to refine our virtual die tryouts. We fine-tune the details of the tools for draw, trim and form and run a full cycle simulation that provides overbend compensation to account for the spring back for the part.

During die design, we build the tools around the surfaces that have been defined in prior steps. We take into account a number of practical considerations such as sizes of customers’ presses, travel, pressures, timing, voided areas versus solid areas, automation and how scrap is removed.

Our goal is first panel to gauge that achieves 95% or better within specification.